Thermoforming Products Plastics Unlimited

Guides 15 minutes read Table of Contents What is Thermoforming? Plastic comes in different sizes, types, colors, and with different material characteristics. The wide variety of plastic makes it a crucial material for manufacturers interested in producing both prototypes and end-use parts for use.

Thermoforming Plastics and Thermosetting Plastics GCSE Design and Technology AQA Revision

Resin is a really good example of a thermoset plastic. None of these plastics can be recycled. Thermoplastic Thermoplastics is a plastic polymer which becomes soft when heated and hard when cooled. Thermoplastic materials can be cooled and heated several times: when they are heated, they melt to a liquid and when they cool they become hard.

Understanding Thermoforming Plastics Resources Inc.

Step 1 is to heat the plastic sheet to a pliable temperature, then shape it to the mold using vacuum pressure, air pressure or a combination of both. Once the material has formed to the mold, it's cooled and removed from the mold, keeping its final shape. Since the final project cools against the mold surface under ambient temperatures.

Thermoforming · Min Plastics & Supply, Inc.

The process of thermoforming. In the thermoforming process, a thermoplastic sheet is heated to a temperature where it is pliable. It is, then, stretched over a mould and held in place while it cools and solidifies into the desired shape. The thermoplastic sheet is clamped and heated by an oven using either convection or heat until it is melted.

Solution to problems associated with PET Thermoform plastic Packaging South Asia

Plastic Thermoforming is a plastic manufacturing process that applies a force (vacuum or pressure) to stretch a sheet of heated thermoplastic material (thermo) over an engineered mold to create a 3-dimensional shape or part (forming).

Thermoforming_1 Advanced Plastiform, Inc.

The process is accomplished by applying heat and pressure (positive or negative) to stretch and conform a two dimensional thermoplastic sheet material onto temperature controlled molds to create custom three dimensional shaped structures and parts. PRIMARY FORMING TECHNIQUES

Thermoforming in plastics processing Greiner Packaging

Plastic sheeting being prepped for heating oven. The process of thermoforming begins by heating thin sheets of thermoplastic material until it becomes pliable and easy to manipulate. While still hot, the plastic is placed onto a rigid backing platform which is most often referred to as a mold. The material is secured by either vacuum pressure.

Thermoforming · Min Plastics & Supply, Inc.

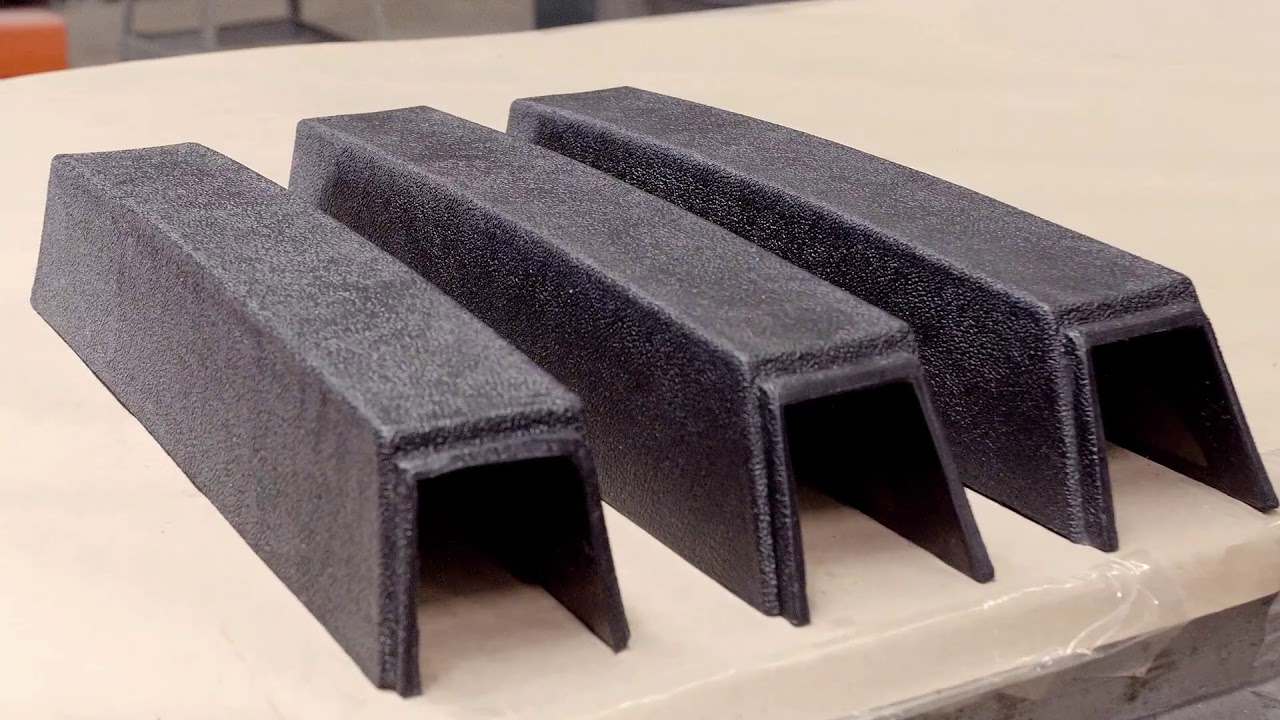

forming can be ideal when you need durable plastic parts that don't require sharp non-tool side features. Applications: • Non-critical appearance covers, dunnage trays, internal. Thermoforming Design Guide • www.Thermoform.com. Example #2. Assume a part size of 10" x 11" x 5" deep. Surface Area = 2(10" x 5") + 2(11" x 5.

Accelerating Growth with Thermoforming Equipment SupplyOne

Procedure A person holds a mold in an open vacuum bed. A sheet of hot plastic will be placed on top and the bed sealed, pulling the plastic down over the mold.

What is Thermoforming? Dienamics

Noryl® Engineering plastic with outstanding strength, stiffness, and electrical insulating properties. PETG Transparent plastic sheet with good impact resistance and outstanding thermoforming characteristics. Polycarbonate Transparent, strong and stiff thermoplastic with outstanding impact resistance. Polycarbonate Film

Thermoforming Process Ultimate Guide 2019 With Cost Examples

PETG Plastic PETG, or polyethylene terephthalate - glycol modified has good clarity, impact strength, and moderate resistance to acids and alkalis. PETG is relatively easy to thermoform and can be heat or RF (radio frequency) sealed without getting cloudy.

a row of plastic stadium seats

A thermoforming primer. First, some basics: The process takes the form of either vacuum or pressure forming. In the former, a heated, pliable plastic sheet is pulled against the contours of the mold by vacuum pressure. "Since pressure is only applied to one side of the sheet," explains Formed Plastics Inc., "vacuum forming is typically.

Professional Plastics Thermoforming Video YouTube

Some of the most common are: Introduction Vacuum Forming: This is the most basic process. In vacuum forming, vacuum alone is used to mold the part. The forming "pressure" is thereby limited to atmospheric pressure, about 14.7 psi. Pressure Forming: In pressure forming a pressure box is used on the side of the part opposite the mold.

Which Plastic Materials Are Used In Thermoforming?

Examples: ABS, HIPS, Polycarbonate Semi-crystalline thermoplastics Difficult to thermoform Examples: HDPE, PP Thermoplastic Triangle HDPE Semicrystalline, difficult to thermoform

Thermoforming Plastics Unlimited

. Thermoforming polymers Thermoforming polymers can be heated and formed repeatedly. They are pliable and recyclable . Acrylic sheet being laser cut PVC window frames 1 of 2 Slide 1 of 2, A.

Thermoformed Products Lyle Industries

Vacuum forming, a low-cost thermoforming process, offers an economical method of creating large-size, low-volume plastic parts. As a custom thermoforming specialist, Universal Plastics has all the answers to your vacuum forming questions. Read through the most frequently asked questions below, or call us at 800-553-0120 for more information.